Inspection Services

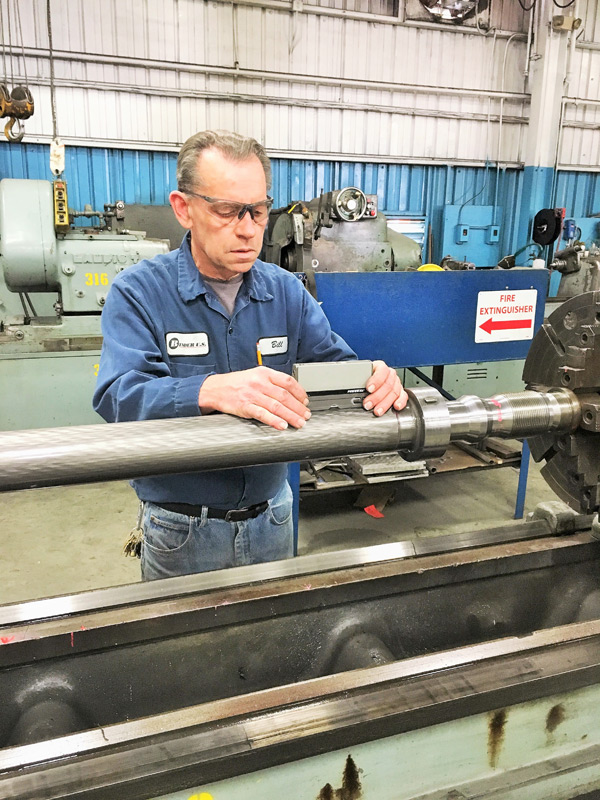

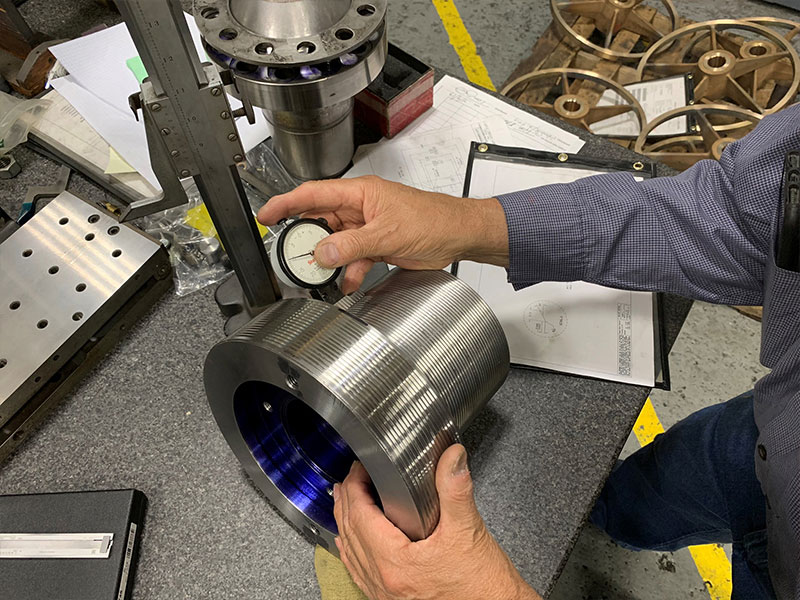

Many of our repair and machining projects start with customers who request onsite inspections, or send equipment to our shop during routine maintenance checks, where our inspectors help identify issues that can cause rotating equipment fatigue or failure before it causes unplanned down time.

PREVENT UNPLANNED DOWN TIME

Highly Accurate Findings You Can Trust

Using the latest technology in equipment inspection

Our inspectors have the latest technology available, which results in highly accurate findings.

Inspection services include:

- Static and Dynamic Balancing of rotors from 500lbs to 20,000 lbs

- Material Identification

- Part Inspection using FARO Arm or Faro Laser measurement.

- Reverse engineering of new equipment casing cast

- Reverse engineering of components such as a pump case

- Vibration Analysis

- Inspect equipment component runouts, diameters, and other dimensions by setting up in lathes or mills

- Laser, optical, or reverse dial indicator alignments of components in the shop or field

In cases where failure has occurred, we are able to quickly inspect, assess and provide emergency repair onsite.