Compressor Repair

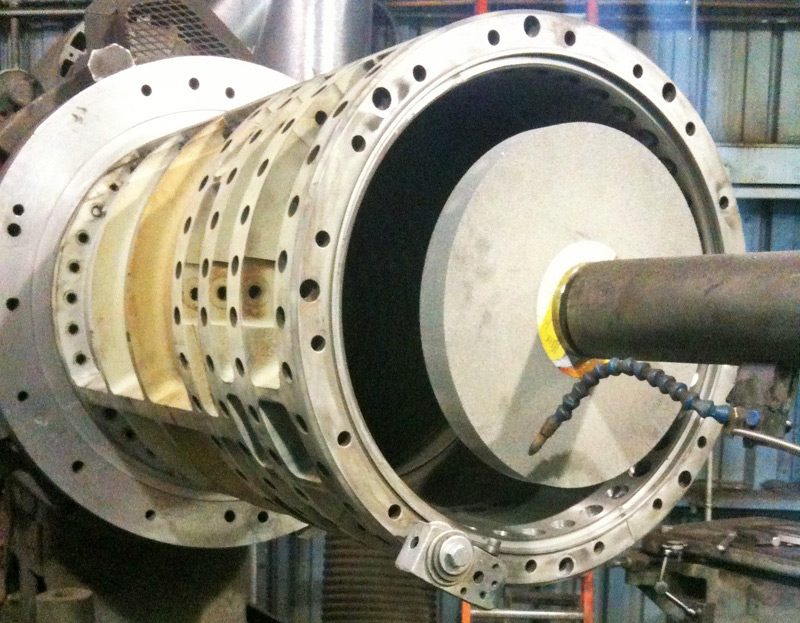

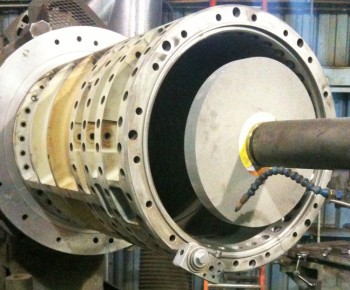

Bender CCP will overhaul your in-service compressor cylinders, reestablishing all factor tolerances at a fraction of the cost of replacement cylinders. Our large machining capacity allows us to easily manufacture replacement cylinder liners to meet project specifications.

FIFTY YEARS OF EXPERIENCE

Largest capacity for reworking reciprocating compressor cylinders on the West Coast

Experience with cylinders ranging in size from 2” – 40”

Our staff has over fifty years of experience reworking Reciprocating compressor cylinders and has the largest capacity on the west coast. We have experience with cylinders ranging in size from 2” – 40”. Bender CCP uses high quality spun cast iron that meets or exceeds OEM requirements. All cylinders are power honed to finish size and to produce the desired surface finish.

Delivery of refurbished equipment can be accomplished quickly due to the size of the facility and the fact that we work two shifts. In turnaround situations our crews work around the clock to meet project schedules.

Bender CCP typically encourages customers to provide the head during a liner replacement to ensure proper fit and to ensure that the head once installed has the rod bore concentric with the liner bore. The head may require skim cutting to make faces flat and perpendicular to the bores. Bender CCP can also replace studs, tap valve holes, repaint the cylinder, and repair damaged surfaces. It is our intent to catch any potential issues up front and to return your equipment in the desired state the first time.

A cylinder relining may also be required due to changes in field operations. Bender CCP can easily reverse engineer a liner or manufacture a replacement liner to accommodate a different size piston.

It is common to manufacture a rough turned liner to put into warehouse stock to reduce turnaround time during a shutdown. Bender CCP will manufacture a liners and endcaps (for later finish turning) to accommodate such requests.

Compressor Rods

Bender CCP has developed a reputation on the West Coast as the premier thermal spray facility for new and refurbished compressor components. Bender CCP is the preferred choice of manufacturers and end users for compressor rods. We have experience with extreme service applications such as H2S and Acid Gas. With the use of surface treatment applied with our HVOF guns and by proper alloy selection we can extend the life of your piston rods. Bender CCP has several Tungsten Carbide coatings that perform well and have a great track record.

- All Rods Feature Rolled Threads

- Super Finished Rod Surface

- All Components Meet or Exceed OEM Specifications

- Designed for Segmental or One Piece Pistons

- Tungsten Carbide Coating

- Custom Design and Manufacturing

- Induction Hardened Rods Available

Rod Refurbishment Process

- Clean and Micrometer Inspect and Record Sizes

- Inspect Rod for Scoring, Cracking, Damage Etc.

- Create a Work Scope with Required Repairs

- Remove and Existing Coatings & Prep for HVOF Spray

- Perform Complete Inspection of Refurbished Rod

- Inspect Piston Grooves and Faces & Repair as Needed

- Check and Record Rod Runout

- Remove Piston & Nut if Necessary

- Consult with Customer

- Grind & Superfinish Rod

- Reinstall Piston and Rider Bands Etc

- Box and Crate to Protect

Piston Manufacturing

Bender will machine pistons from cast iron or aluminum. Bender can manufacture one piece pistons or segmental pistons. Bender CCP can reverse engineer pistons to match existing installation or upgrade as required. Bender CCP will produce drawings and provide to the customer as requested.

Replacement Parts For

- Worthington

- Cooper-Bessemer

- Deleval

- Joy

- Ajax

- Dresser-Rand

- Clark

- Demag

- Superior

Quality

- ISO 9002 Certified Procedures

- Equipped with State of the Art Equipment

- Experienced Production Staff

- One Year Full Warranty of Materials and Workmanship

Valve Refurbishment

Bender CCP will recondition your compressor valves to OEM specification at a substantial savings vs. replacement. The typical turnaround on a set of valves can be accomplished in about a week or quicker during a shutdown.

Repair Process

- Disassemble, Clean, Visually Inspect & Record Dimensions

- Glass Bead Blast Valves

- Surface Grind Mating Surfaces

- Lap Mating Surfaces

- Lift, Seat Thickness, Spring Pocket Depth Checked

- After Assembly Air Test

- Parts Identified, Tagged & Bagged

- Machine and Mill as Necessary Damaged Areas

- Use Emery Paper to Debur

- Clean Parts

- Install Replacement Parts

- Package Valves

Type of Valve Serviced

- Poppet Valves

- Plate Valves

- Strip Valves

- Channel Valves

Packing Box Refurbishment

Bender CCP can refurbish the packing cases for your reciprocating compressors. We will dissemble clean and inspect all components, procure or manufacture replacement parts and return your packing cases in like new condition.

- Machine all Pressure and Wiper Cups

- Machine, Grind, and Lap Finish

- Rap and Preserve Finished Packing Cases

- Replace nose cup seal ring

- Reassemble, Final Inspect, Record Dimensions

Unloaders

- Disassemble, Clean, Inspect

- Inspect Rods

- Air Test for Actuation

- Replace Seals & Rings

- Metal Spray Bores in Unloaders if Needed

- Paint

Connecting Rods

- Dimensional Inspection to Confirm Round

- Check for Damage

- Confirm Bore Size and Parallelism

- Re-machine as Necessary

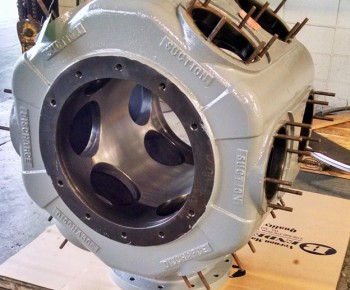

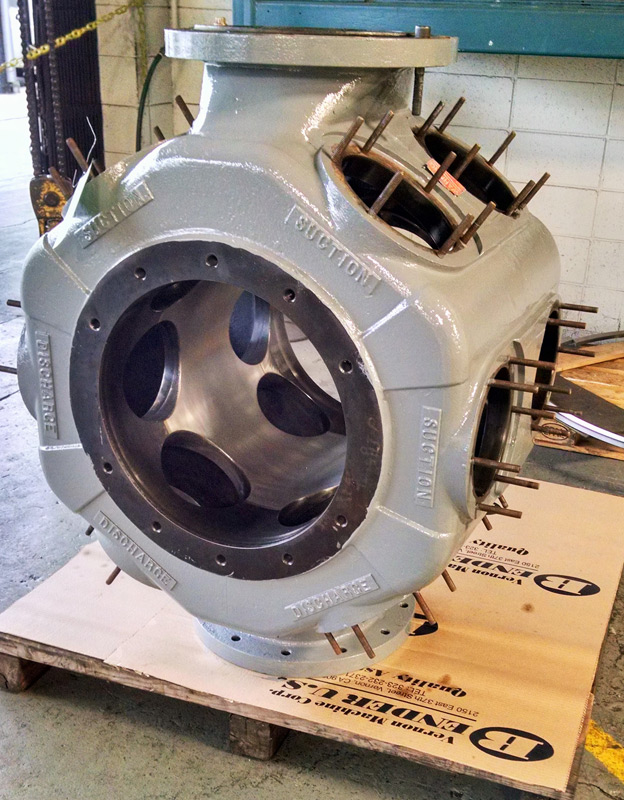

Compressor Case

- Line Boring

- Bore Alignment

- Rebabbit Cross Head Slippers

Cross Head

- Clean & Inspect for Scoring and Sizing

- Confirm That Runs True with Crosshead Pin

- Confirm Bore Size and Parallelism

- Re-machine as Necessary

Crank

- NDE Inspection

- Balancing

- Inspect Journals and Dimensions

Valve Retainer Cage

- Clean & Inspect for Pits / Cracks

- Glass Bead Blast

Metal Spray Cylinder Refurbishment

- Metco #2 Spray (420 SS)

- Wire Arc Spray